Kn-10

Product Details

BTUs

1,000,000

efficiency

90%

Fuel Type

Natural Gas/Propane

Footprint *

72” x 36” x 50” HWD

Contact Representative

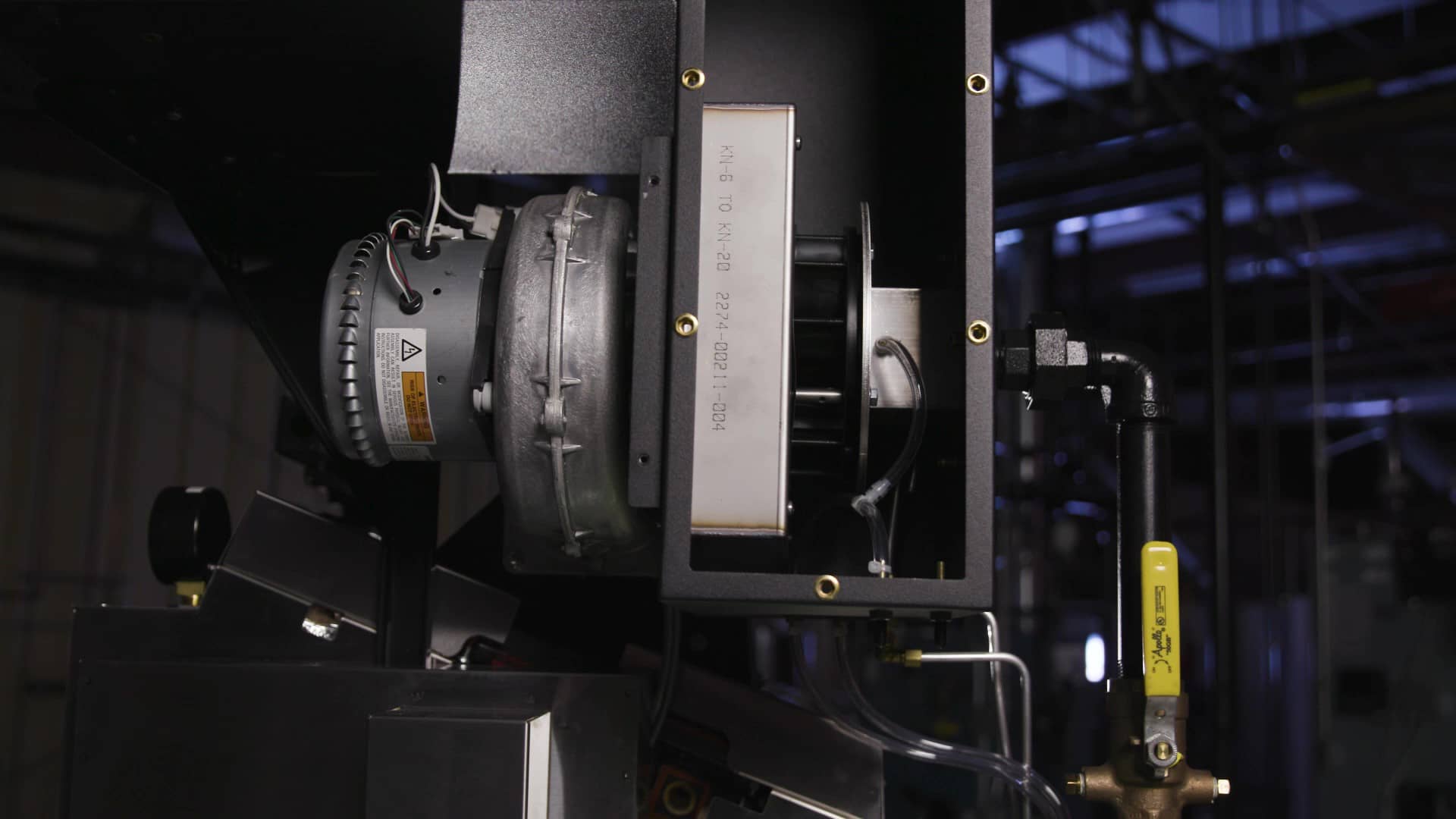

Cast Iron Heat Exchanger – Durable and Reliable

Why Cast Iron

An ideal material for condensing boiler applications, cast iron is produced using casted metal, making the construction stronger than metals that are welded together. With fewer seams and joints, KN-Series' cast iron heat exchangers can handle more heat and more stress. And with corrosion-resistant properties, cast iron is inherently less sensitive to both acidic and basic pH levels. With the strength, durability and longevity needed for today's most demanding boiler applications, the cast iron technology sets KN-Series condensing boilers apart from the competition.

Literature & Downloads