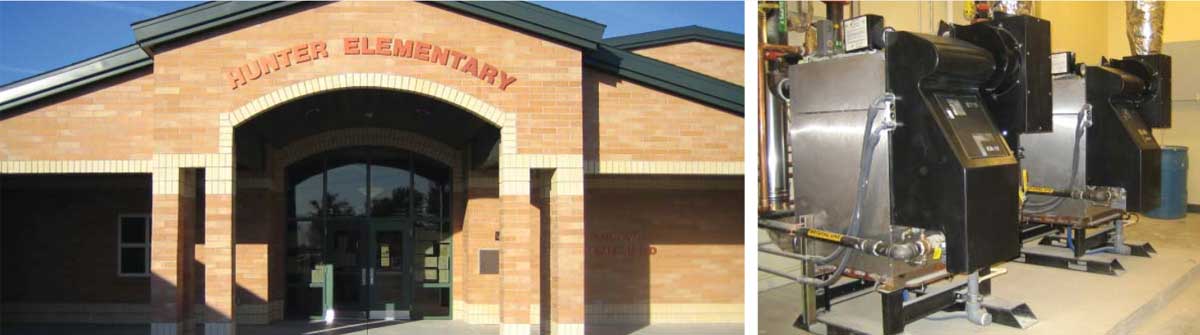

Hunter Elementary School

When it comes to commercial boilers, the mantra of the day is high efficiency. The higher, the better ' especially in these days of $3-a-gallon gasoline and skyrocketing heating fuel costs. It's bad enough for commercial business enterprises, but for schools and other entities that generally struggle with budgets, it's even worse. And while there's no relief in sight, there are options for facility managers who are looking to stretch their heating dollars.

In planning for its newest elementary school, the Joint School Distric of Meridian, ID, required a high-effi ciency HVAC system that would also be easy to maintain. A low-temperature hydronic system featuring condensing boilers was selected to economically serve the school’s needs for years to come.

Such is the case with the Joint School District of Meridian, Idaho. The Joint School District today serves over 30,000 students, and is the largest and fastest growing school district in Idaho. To keep up with growth and to ease overcrowding in other area schools, the district built the new Hunter Elementary School, which opened in the fall of 2005. Hunter Elementary is now home to nearly 800 students. To meet the school's boiler needs, the school district required a high-efficiency system that is also easy to maintain ' a tall order, to say the least. The answer was a state-of-the-art heat pump system that would economically serve the school's needs for a long time to come.

Hunter Elementrary's new HVAC system was designed by Charles Paulin (PE) of Musgrove Engineering PA of Boise. He specified the heat pump system for long-term efficiency and life expectancy despite the increased up-front costs. The low-temperature hydronic system is ideal for condensing boilers, as they eliminate the need for low water temperature protection inherent with non-condensing boilers, and they generally offer higher operating efficiencies. Buss Mechanical Services, also of Boise, was awarded the mechanical work for the project and owner Lenny Buss selected two KN10 boilers for the job.

'A real obstacle in this project was the sheetrocking on the underside of the structure,' said Buss. 'Since the sheetrock could not be installed until the roofing was completed, the mechanical installation time frame was greatly reduced. The key for the on-time completion of the total mechanical system was the fact that we prefabricated, on the floor, all overhead piping in the corridors. After the sheetrock was installed, we were able to hang our prefab piping quickly and stay on schedule.'

The KN10 is one of the newest commercial boilers from Advanced Thermal Hydronics, a Mestek company. The commercial gas-fired cast iron condensing boiler features unique 'Tru-Flow' technology to control the fuel-air mixture at all firing rates and venting conditions. The combustion air is constantly measured to fine-tune the fuel gas flow for maximum efficiency. In addition, the boiler takes full advantage of the condensing feature by allowing it to operate at a system return water temperature of less than 128F with no return water temperature limitation. These boilers are capable of maintaining temperature differentials of up to 100F, and offer one of the best warranties in the market.

'The KN-10 was the natural choice for this project,' said Trevor Thompson of Columbia Hydronics Company, a manufacturers' representative firm with offices in Boise and throughout the West. 'The KN10 offers many unique features that go above and beyond the project requirements that will benefit the school district for years to come.' Besides the boiler system, the system includes two other significant pieces of equipment: the cooling tower and the circulating pumps required to move the fluid throughout the system.

The cooling tower specified is a Baltimore Aircoil (BAC) closed-circuit, evaporative cooling tower, which rejects heat from the building. The 160-ton BAC tower was specified because the evaporative cooling technology makes it possible to cool or condense to a lower temperature than simple dry-air cooling, saving space, equipment cost and energy consumption ' all important considerations for the Hunter Elementary project. The Hunter Elementary project required circulating pumps with a rating of 401 GPM, and for that task, Musgrove Engineering specified two Bell & Gossett Series 1510 base-mounted pumps. To control this equipment, the project included a DDC control system, featuring BACNET protocol, by Automated Logic Corporation. This system, installed by Clima-Tech Corporation of Boise, provided the two-stage boiler operation, three-stage cooling tower operation, and lead/lag controls for the system pumps, as well as the system heat pumps and ventilation system controls.

Back on the boiler front, one of the key elements of the KN10 is that the boiler comes standard with full modulation. The result: reduced utility expenses for the life of the boiler. Although the KN10 can be fired on-off, the full modulation system offers the opportunity for the boiler to operate at higher efficiencies. This is a deviation from the standard boiler system design used throughout the school district where two boilers were enabled/disabled (on-off fired) by a building automation system rather than a modulating system. As an example, the KN10's efficiency is approximately 88% at highfire, with return water temperatures near 60F as they will be in the heat pump loop. With the same water temperature, but with the boiler at 1/3 input, the operating efficiency jumps to nearly 98%.

'Modulation is now an integral part of the system,' said Thompson of CHC, 'and using the KN10 boilers did not require any changes to the original system design by Musgrove Engineering. The BAS is still only enabling/disabling each boiler as required by the building's heat pump loop temperature. However, each KN10 boiler includes an independent, factory-wired controller that smoothly modulates the boiler via a PID algorithm.' The KN series now features three boilers with 600 MBH, 1,000 MBH, and 2,000 MBH ratings, with up to 5:1 capacity modulation, low CO and NOx emissions of less than 20 ppm to meet SCAQMD (rule 1146.2), and whisper quiet operation ' and all in a unit with a footprint of less than 29-inches wide.

'Our relationship with the Joint School District in Meridian Idaho is extremely valuable to us both professionally and personally,' said Paulin. 'When we consider equipment alternatives to our basis of design, we need to feel confident in the equipment and the local representation. To date, the KN-10 boilers have worked well and Columbia Hydronics has provided the support to make the equipment installation a success.'